Written by: Merijn Koolstra

Intermodal Transport | 5 mins read

– Intermodal container transport refers to transport for which two or more modes of transport are used. Loading units (containers or swap bodies) are used for this type of transport. By using these standardized load units, goods can be transported faster and easier. This is because containers can be exchanged one-to-one between the different modes of transport. Furthermore, this type of transport is also safer and there is less risk of damage compared to conventional transport.

In the Netherlands alone, 4.5 million containers are unloaded in Dutch ports every year. The majority of these containers arrive in the port of Rotterdam. From this sea port, the containers continue their way via inland shipping, rail or road. Over time more and more inland terminals are connected to inland waterways, rail and road. These inland terminals reduce the pressure on the deep sea terminals, such that the container flow is better distributed. Intermodal (container) transport is currently, indispensable in our society. To manage, plan, trace and administrate container transports a complete and ‘smart’ IT solution is needed.

Intermodal Container Transport

In the Netherlands alone, 4.5 million containers are unloaded in Dutch ports every year.The logistics activities related to intermodal (container) transport are divided into the following categories:

- Container Management – managing container flows and making containers available for the transport of goods. Shippers may use their own containers or the containers are leased for a short or long period of time. Given the enormous numbers of containers used worldwide, it is important for parties involved to monitor the flow carefully to ensure no stagnations in transport is happening due to the unavailability of containers.

- Container transportation – covers basically all activities related to the physical transport of the containers throughout the chain. As indicated earlier, this can be done via various modes of transport. The activities taken place at the (inland) terminals and at the depots are also part of the transport.

- Container handling – covers all activities related to the handling of the containers. This includes loading and unloading containers, securing cargo in a container, putting the container load on pallets, etc.

- Container storage and maintenance – concern the activities required prior to the actual transport as well as after the transport. If the goods have been unloaded from a container, the container is taken to a depot waiting for the next transport. Cleaning and repairing containers are also part of these activities.

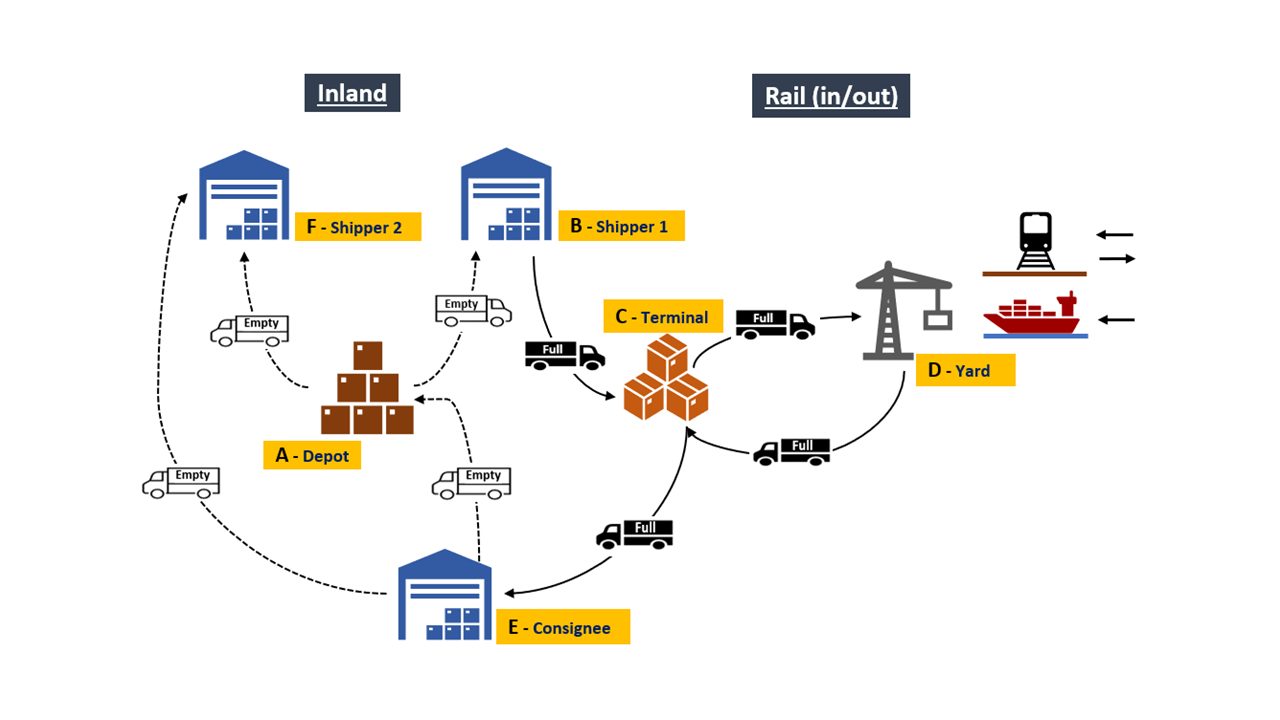

Status flow of a container transport

All mentioned activities are related to the transport of goods from A to B using a container. For an intermodal operator or freight forwarder it is important to know the status of a particular container at any moment in the process. This “status” is the transport status of a container. In principle, the transport status of a container follows the progress of the transport. In the next picture a simplified representation of the flow of the transport (= round trip) for a container (step A to F) is presented.

Intermodal Container Transport

For an intermodal operator or freight forwarder it is important to know the status of a particular container at any moment in the process.Depending on the services an intermodal operator or freight forwarder offers to its customers, only a couple of above steps can apply or all of them. The following services apply to the different steps (A to F) in the drawing:

- Providing an empty container for transport

- First mile (transport)

- picking up a container at a depot or warehouse

- delivery of a container on a terminal

- Customs

- Main transport by Rail

- registering of incoming shipments by rail or (ocean) vessel

- Last mile (transport)

- picking up a container on a terminal

- delivery of a container to a warehouse

- delivery of a container (empty) on depot.

The related transport statuses for a container based on the above transport flow are:

- Ready to be picked up at depot (A)

- Picked up from depot (A)

- Delivered for loading (B), (F)

- Waiting for customs (B)

- Released by customs (B)

- Released for transport (B), (C)

- Arrived at terminal (C)

- Loaded on rail / ship (D)

- Departed from terminal (D)

- Handed over (D)

- Takeover at terminal (C)

- Picked up at terminal (C)

- Delivered for unloading (E)

- Delivered at depot (A)

Good communication between systems (involved parties) is essential for efficient control and handling of these intermodal container transports. This implies communication between:

- Rail carrier and (sea) terminal

- Sea terminal and inland terminal

- Rail carrier and customs

- Shipper and rail carrier (directly or through a forwarder)

- Rail carrier and depot.

For this communication it is important that all data relating to a container transport is well documented in a system. This concerns the following data:

- Parties involved (shipper, customer, carriers, etc.)

- Data on the content of the transport

- number and type of containers

- content of the load (containers)

- Departure and arrival times

- Status flow of the container(s)

- Documentation required for transportation

- Bill of Lading

- CMR

- Certificates

- Train list

- Costs related to the transport.

Intermodal Container Transport

Good communication between systems (involved parties) is essential for efficient control and handling of these intermodal container transports.Ab Ovo offers the 4RailCargo SaaS solution to rail transportation companies

This is a full ‘order to cash’ solution, that covers all the points described above. The system has a focus on rail transport with additional freight forwarding functionalities, and supports the following:

- Container transports by rail can be handled completely from creating a transport order to the final invoicing of this order.

- The status flow for a container (as described in this BLOG) is integrated

- The optimal route for a transport can be determined

- Containers can be planned on trains via a smart algorithm

- The pre-transport and/or post-transport can be determined for a specific (rail) transport

- Containers can be managed

- availability of containers

- reservation of containers used for a specific transport

- registration of container events

- UN EDIFACT Container Messages are supported to communicate the status of a container between terminal, depot and carrier.

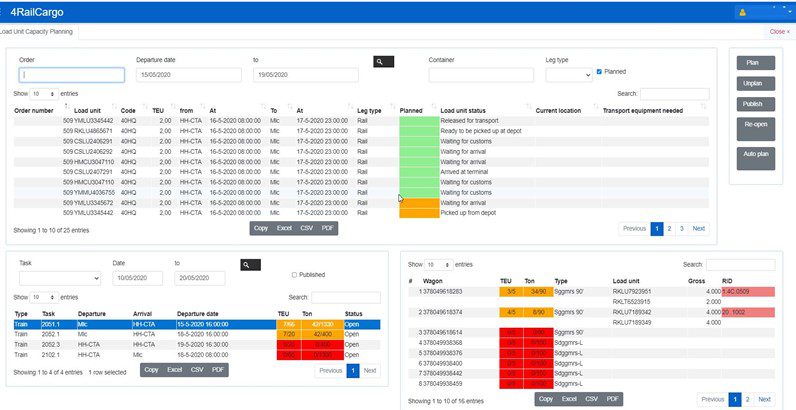

The main user interface for managing and planning of containers on trains/wagons is presented below; it gives a complete overview of planned and available capacity using colors and quantities in TEU and Ton:

- In the top list the containers of orders that must be planned, are visible with their status.

- In the bottom left list the train legs are displayed with their available and planned capacity

- In the bottom right list all the wagons on a specific train leg are displayed, including the planned containers and the remaining capacity.

For the planning two algorithms are used: one for optimal route derivation through the available capacity and one for the optimal loading of the containers on the wagons.

More information

For more information, please contact Merijn Koolstra via merijn.koolstra@ab-ovo.com or request a discovery session to learn more about intermodal container transport.

Merijn Koolstra is a business consultant and has been working for Ab Ovo for more than 8 years. He studied logistics in Rotterdam and has more than 15 years of experience in the world of transport and logistics so he knows what he is talking about. Looking for smart (IT) solutions for business processes together with the customer is something he gets enthusiastic about.